Control Cables

Complete Production

Stork Auto follows a systematic procedure for production. New samples are studied by the product development team, drawing measurements are recorded and archived. Test reports for each product are also archived. After this, CAD drawing and tooling is done for each cable. Each individual component of the cable is checked, drawn up, tooled and then produced in-house and by dedicated vendors.

Prototypes produced are subjected to extensive testing including endurance before being put into production. At Stork Auto we currently develop around 30 new cables every month for our OE and after market customers.

A complete in-house production of components gives Stork Auto an extra edge over other manufacturers.

Control Cables

- Brake Cables

- Clutch Cables

- Gear Shifter Cables

- Accelerator Cables

- Speedometer Cables

- Seat Adjuster Cables

- Cables for Tractors & Fork Lifts

- Window Winder Cables

- Hood Release Cables

- Cables for Industrial Applications

- Precision Turned Parts

Assembly Line

5 assembly lines produce with the aid of skilled labour over 3,00,000 cables for 4 wheelers per month on a single shift basis. Each cable is carefully put together and each component and crimp checked and double checked. We do 100% quality and proof load testing on each and every brake and clutch cable we produce.

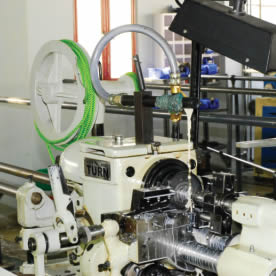

Control Cables Facility

Founded in 2000, Stork Auto Engineering Pvt. Ltd., is engaged in the manufacturing of world class Control Cables, combining technological sophistication and state-of-the-art production facility.