Quality and Lab

Quality is not a process by itself. It is not a requirement which is met by a single person or a team of people. Quality is a way of working, a part of the process of manufacturing, it is in-built into the culture at Stork. We follow a philosophy of Make no defect, accept no defect and give no defect. As a result each product has an employee who stands behind the integrity of each part supplied by Stork. Just like every other manufacturer, it is not possible to have 0 defects. When our customer reports are defect, we follow an 8D problem solving approach to pinpoint the step of the process that failed and we improve the process to prevent further defects and simultaneously we solve the issue for our customer.

Our lab is constantly in use with a rigorous testing schedule for the parts manufactured in routine by us . All automotive bushes are routinely endurance tested upto 3 million cycles on 3-axis and single axis benches.

Our lab is constantly in use with a rigorous testing schedule for the parts manufactured in routine by us . All automotive bushes are routinely endurance tested upto 3 million cycles on 3-axis and single axis benches.

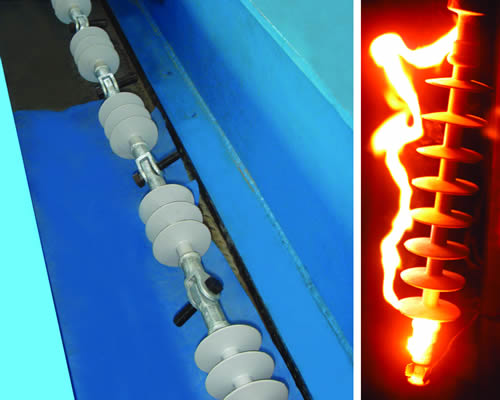

Insulator batches are routinely subject to thermo-mechanical stresses, UV ageing and hydrophobicity recovery to ensure that the moulding and crimping parameters are as per the design and type tested process.